Temposensor Basic

A basic requirement for sustainable and efficient farming is the adequate application of input materials used in order to optimize costs, and also the related yields in addition to reducing environmental burden.

To be in compliance with such good practices, we developed an unique solution with the following opportunities for farmers:

- TempoSensor Basic: ensures Phylazonit application adjusted to speed.

- TempoSensor Precision: allows different amounts of Phylazonit to be distributed on the designated area according to defined zones.

- TempoSensor Precision Nitrosol (a liquid nitrogen fertilizer): has the basic and precision application options listed above. The amount of Nitrosol that can be applied is always maximized by the working width and speed.

With these solutions, we are 100% capable of meeting all the requirements of precision application while also having the capacity to provide the technical, mounting, and operational support to our farmers additionally.

Advantages of Temposensor Basic:

The Temposensor Basic changes the applied dose in accordance with the speed of the work machine. During turns or when the work machine is lifted or stopped, will the application of Phylazonit be stopped thus ensuring that the product is evenly distributed throughout every point in the targeted area in the desired quantity planned for. One can be sure that if a doseage of 15l/ha is calculated and for a 100-hectare field, 1500 liters of Phylazonit will be sufficient and from that 15 l/ha can be applied to all parts of the 100-hectare field.

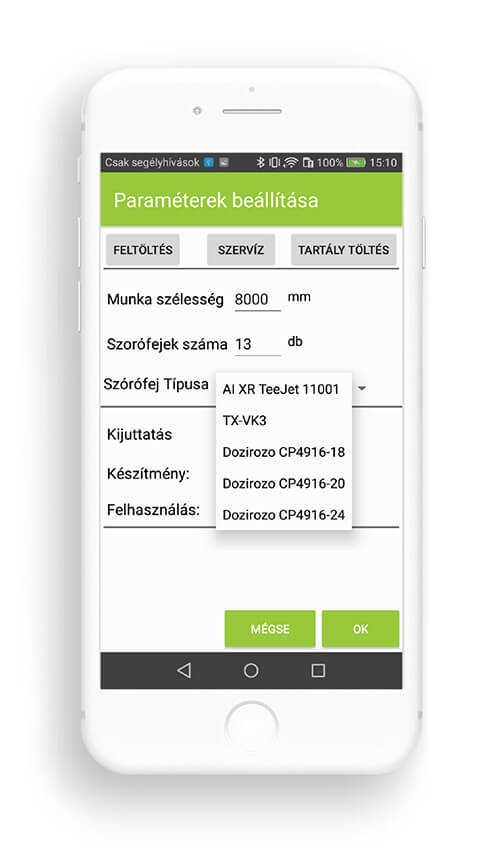

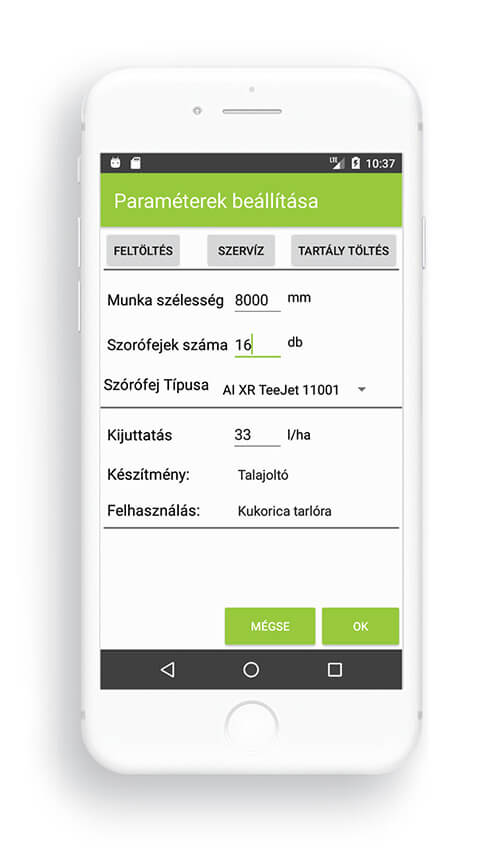

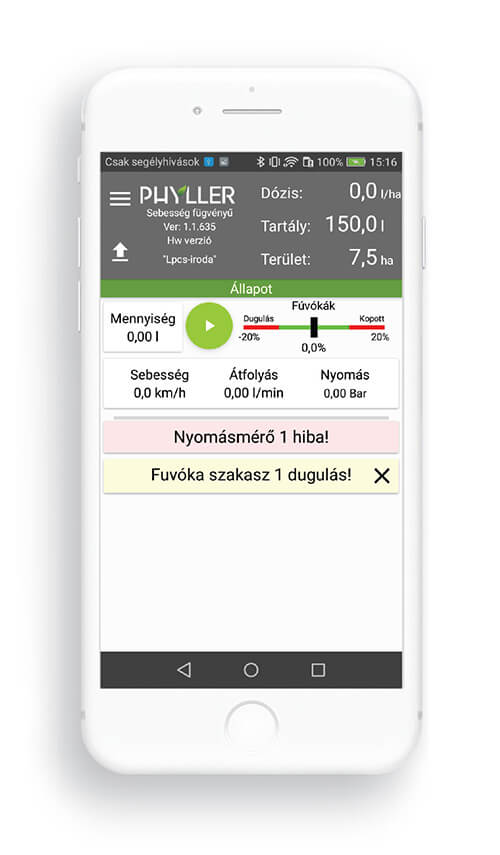

The controller unit ensuring speed rate-based application calculates the right fluid volume at any given time from data such as real-time speed, working width and dose per hectare to be applied. The defined dose is determined by a preset value on the user interface, which is sent to the controller. Speed measurement and locating is done by the built-in special GPS unit. The Temposensor Basic uses a spring-loaded limit switch on the machine to sense the raised position and to pause application during headland turns. The system measures the amount of liquid flowing through the nozzles and adjusts the flow rate accordingly to the pump performance so that the desired s10ml/ per minute is maintained.

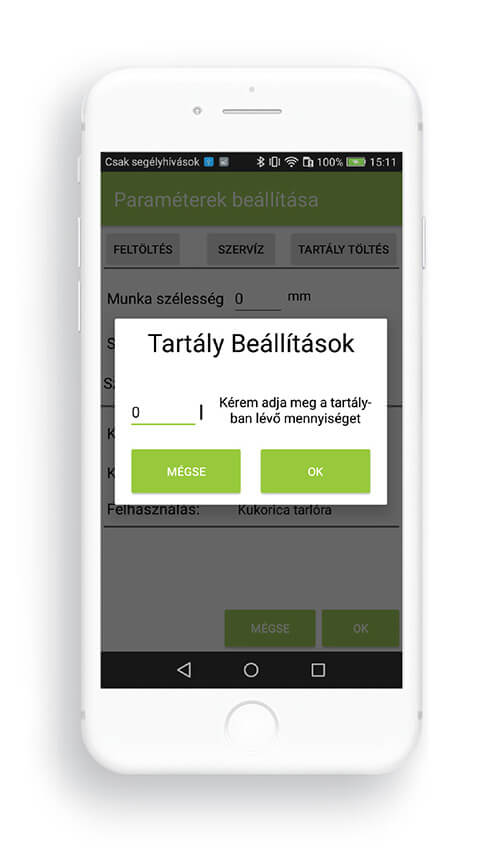

If the system experiences a value other than what the settings allow, it indicates the cause of the possible error in an alert message. It also detects and indicates filter clogging and pipe leakage. It continually calculates and indicates the amount of liquid in the tank, and based on this, estimates the size of the remaining area